- Avia

- Allison Transmission

- Aichi

- Astra

- BAW

- BOBCAT

- Case

- Caterpillar

- Crown

- Cummins

- Challenger

- Claas

- Daewoo

- DAF

- Daihatsu

- Detroit Diesel

- Deutz

- Dongfeng

- Doosan

- Eaton

- Fendt

- Freightliner

- Hino

- Hyundai

- Iveco

- JCB

- JAC

- John Deere

- Jungheinrich

- Kenworth

- KIA

- Kubota

- Mack

- Man

- Massey Ferguson

- Mercedes

- Mitsubishi

- NEW HOLLAND

- Nissan

- Paccar

- Perkins

- Peterbilt

- Renault

- Scania

- Shaanxi

- Shacman Fault Codes

- Toyota Forklift

- VAG

- Volvo

- Webasto

Toyota Forklift Service Repair Manual

Toyota Forklift Service Repair Manual

Workshop manuals, service manuals, repair manuals, parts, technical documentation and parts catalogs.

WIRING DIAGRAM

Note for operators and mechanics

Before starting operation

Caution Labels

The main components

Driving controls and dashboard

Measuring instruments

Switches and levers

Body Components

Pre-operational inspection

Before placing a vehicle in a garage

Weekly Maintenance

Independent maintenance

Checking the fuel tank

Frame serial number

How to read the nameplate

Lubrication Scheme

Periodic maintenance

Periodic replacement table

Toyota

Liquefied petroleum gas device (optional)

Switches

LPG tank and related parts

Operation of forklifts operating in the CIS

Regulator Maintenance

Inspection and maintenance of LPG forklifts

Lubrication and coolant

Engine Specifications

Mast specifications and rated loads

Wheels and tires

Periodic Maintenance Chart

Operational data

Overall dimensions of the vehicle

EXTERIOR VIEWS

BOLT STRENGTH TYPE IDENTIFICATION METHOD

VEHICLE MODEL

TIGHTENING TORQUE TABLE

FRAME NUMBER

PRECOAT BOLTS

HOW TO USE THIS MANUAL

EXPLANATION METHOD

TERMINOLOGY

ABBREVIATIONS

HIGH PRESSURE HOSE FITTING TIGHTENING TORQUE

WIRE ROPE SUSPENSION ANGLE LIST

SI UNITS

OPERATIONAL TIPS

SAFE LOAD FOR EACH WlRE ROPE SUSPENSION ANGLE

JACK-UP POINT

HOISTING THE VEHICLE

COMPONENTS WEIGHT

CAUTION FOR TOWING

RECOMMENDED LUBRICANT QUANTITY & TYPES

ATENTIVE POINTS ON SAS

CIRCUIT TESTER

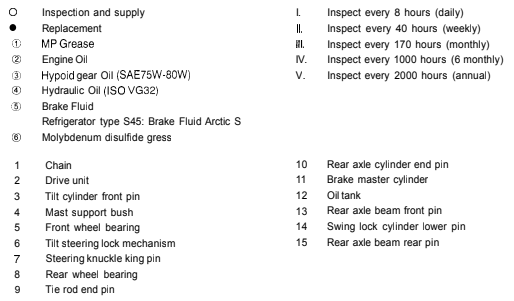

LUBRICATION CHART

STANDARD BOLT & NUT TIGHTENING TORQUE

PERIODIC MAINTENANCE

PERIODIC REPLACEMENT OF PARTS AND LUBRICANTS .

Toyota 7 Series Forklift Lubrication Schemes

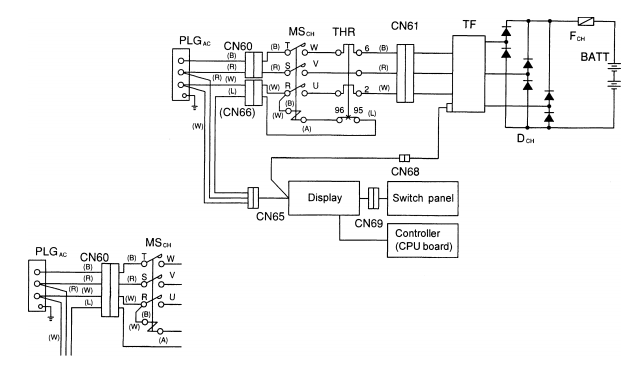

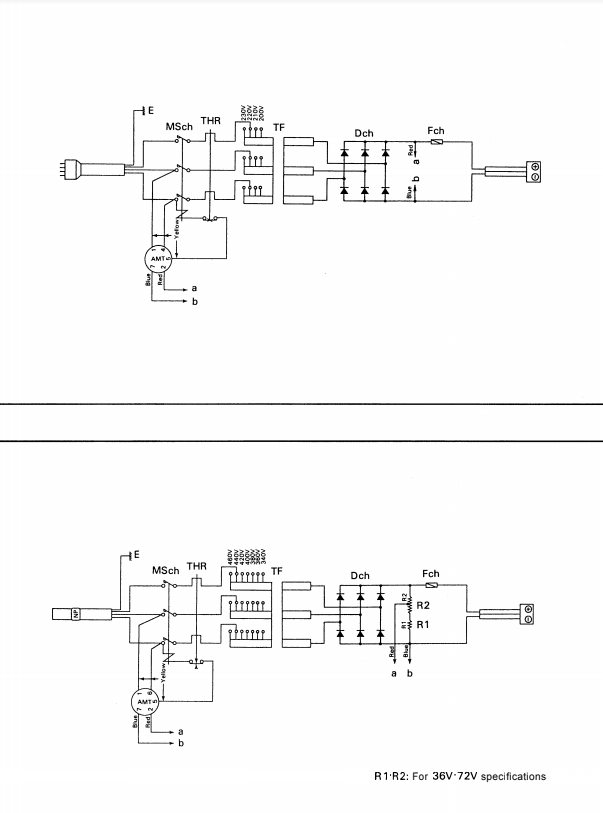

WIRING DIAGRAM

(For 48V 600A or more, 80V 370 - 470AH)

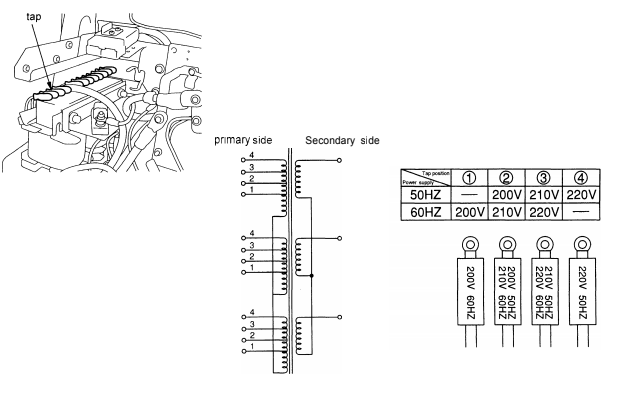

TAP LAYOUT

TRANSFORMER ASSY

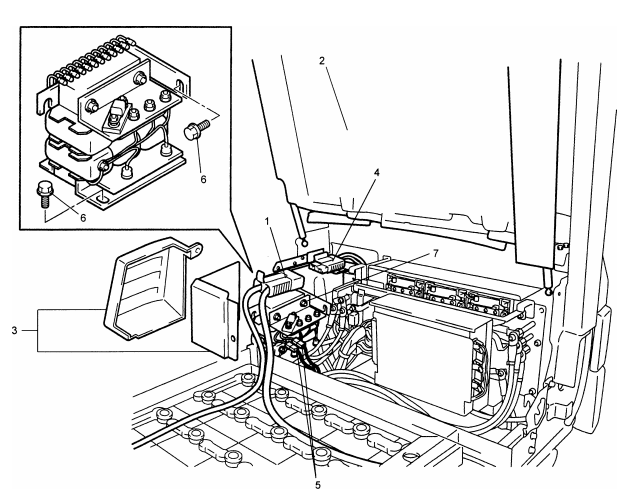

REMOVAL~INSPECTION*INSTALLATION

Removal Procedure

1 Disconnect the battery plug.

2 Remove the seat stand.

3 Remove the louver and transformer cover.

4 Remove the battery plug bracket.

5 Disconnect the CN61. CN68 connector.

6 Remove the transformer ASSY set bolts.

7 Remove the transformer ASSY by hoisting it. [Point I]

Installation Procedure

The installation procedure is the reverse of the removal procedure.

OFF-VEHICLE CHARGER

WIRING DIAGRAM

TROUBLESHOOTING

Estimated cause 1. Short circuit of MSch

Inspection method (1) MSch coil continuity inspection Measurement terminals: A, and A,

Standard OK: Several hundred R NG: Abnormally low resistance

Corrective action MSch replacement

MUHAMMAD UMAIR (Sunday, 30 April 2023 00:56)

Looking for a manual for my Toyota forklift it’s a 6FG33

John (Sunday, 19 February 2023 03:59)

Looking for a manual for my Toyota forklift it’s a 2fg10

Jason (Wednesday, 10 August 2022 16:27)

Please translate the 8fg/8fd manual to english

James Lunceford (Friday, 08 July 2022 19:53)

40 3fu60-60697 electric wiring diagram